Diamond Ridge uses Hover’s new Material List to simplify takeoffs, reduce waste, and preserve their bottom line.

With home construction, no one feels the pressure to maintain project momentum more than the lead contractor.

Yet too often contractors are at the mercy of others – particularly when it comes to material lists and takeoffs. What contractors may need based on specific project nuances and preferences is often missed – resulting in wasted time and inaccurate orders. Many contractors want more control in the process. And Hover provides it.

As an operations manager for Diamond Ridge Construction, Nick Campbell relies on Hover to get the measurements and material quantities he needs to successfully manage his projects and maintain profitability. Based near Cedar Rapids, Iowa, Diamond Ridge hired Nick to support their 5-year-old exteriors, framing, and custom homebuilding business. They’re relying on Nick’s years of experience in distribution to help build their reputation and reach. In turn, Nick is relying on Hover to get orders right.

“Before Hover, we were hurting at both ends,” explained Nick. “We were missing things we needed to build a job and also left with excess material we couldn’t return. It was clear we couldn’t just rely on our distributors to get material orders right. We had to take control on our end too.”

When it comes to production efficiencies, it’s all in the details

Since their launch five years ago, Diamond Ridge had built a solid relationship with their distributor. The only issue? Neither Diamond nor the distributor had anyone experienced enough to do siding takeoffs. Diamond’s siding jobs were then sent to another branch for takeoffs, but too often that branch had their own customer takeoffs to complete and prioritized these over Diamond’s projects.

When Nick came on board, he quickly realized he couldn’t dedicate the time to manually calculate materials and measurement conversions for his estimates. He was also frustrated by the all-too-frequent mistakes on quantities and materials... Something had to change.

“It could take a week if not longer to get a takeoff done, depending on the complexity of the project,” added Nick. But time wasn’t the only issue. Too often their distributor lacked sufficient context on a project and would omit materials on the takeoff, leaving Diamond to wait on reorders or scrambling to source materials elsewhere. “We could either hire somebody to run our takeoffs or save $10,000 and just give it a whirl with Hover.”

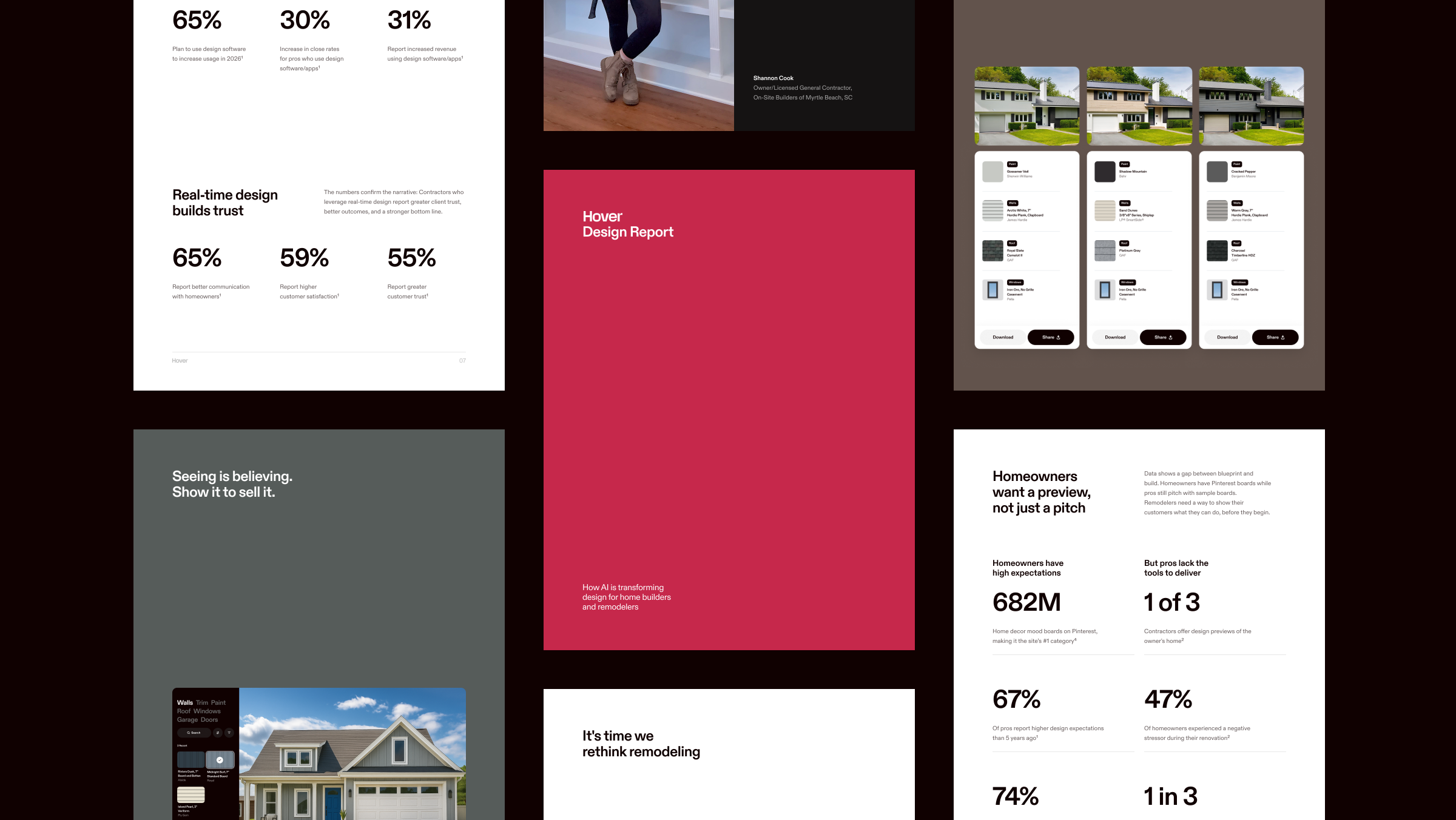

Nick already relied on Hover for measurements and decided to give Hover’s Material List feature a try. After a few trial runs, it was clear to him that generating his own takeoffs would provide the control he wants and the materials he needs.

Today, he uses Hover’s measurements and material list templates to generate takeoffs instantly. He relies on Hover to tell him exactly what materials are needed and how much the job needs. He can customize Hover Material Lists to his own installation and waste preferences. “We’re no longer dependent on our distributor for takeoffs,” he adds. “I am more confident that our orders cover what we need and our crews aren’t waiting days to start the job.”

Tackling new construction with confidence

While using Hover on their exterior renovation jobs was a no-brainer, Nick soon realized the impact Hover could have on new construction.

“I uploaded a blueprint to Hover, had measurements in an hour, and then a material list in seconds,” bragged Nick. It used to take him days to enter measurements, generate a complete material list, run the conversions, and plug-in pricing for an estimate.

Diamond Ridge recently started work on a five-unit building for a local rental company. Nick used Hover Measurements and Material Lists to determine how much shake he needed and where, and how much board and batten siding he needed elsewhere – all from an uploaded set of blueprints.

“If I’ve got five days to turn around an estimate, I can’t wait ten days for a material list,” concludes Nick. “Now, when we’re asked to bid on a project, we can actually turn one around in time. I can easily upload the blueprint, get my material list, and plug in my numbers in less than a day. We can offer a bid that accurately outlines project costs and ensures our margins too.”

With Hover, Diamond Ridge can now ensure accurate, timely takeoffs and orders. Even better, they can bid on more projects and are more confident in tackling everything from single-family to multi-family units.