In today's competitive construction landscape, accurate framing takeoffs are essential for project success. Whether you're a seasoned contractor or new to the field, understanding the nuances of framing takeoffs can significantly impact your project's efficiency and profitability.

What is a framing takeoff?

A framing takeoff is a detailed list of all the framing materials required for a construction project. This includes quantities of lumber, connectors, sheathing, and other components essential for the structural framework. Accurate takeoffs ensure that you procure the right amount of materials, minimizing waste and avoiding costly delays.

Step-by-step guide to performing a framing takeoff

Pro tip: Upload your blueprint plans with Hover for a fully automated framing takeoff. You can even work with the Hover team to customize waste factors and preferred products. Try it for free!

1. Analyze the project plans

Begin by thoroughly reviewing the architectural and structural drawings. Identify all framing elements, including walls, floors, roofs, and openings. Pay close attention to dimensions, material specifications, and any special framing requirements.

2. Quantify wall framing components

-

Studs: Calculate the number of studs by dividing the total wall length by the on-center spacing (typically 16" or 24"). Add additional studs for corners, intersections, and openings.

-

Top and bottom plates: Multiply the wall length by the number of plates (usually three: one bottom and two top) and account for waste.

-

Headers: Determine header sizes and quantities based on opening widths and load requirements.

3. Calculate floor and roof framing materials

-

Joists and rafters: Measure the spans and spacing to determine the number and size of joists and rafters needed.

-

Sheathing: Calculate the area of floors and roofs to estimate the number of sheathing panels required.

4. Include connectors and fasteners

List all necessary connectors, such as joist hangers, hurricane ties, and nails or screws. Ensure that quantities align with framing requirements and local building codes.

5. Factor in waste and contingencies

Add a waste factor (commonly 10-15%) to account for cutting losses, mistakes, and future modifications. This buffer helps prevent material shortages during construction.

Leveraging technology for accurate lumber framing takeoffs

Modern construction software can streamline the takeoff process:

-

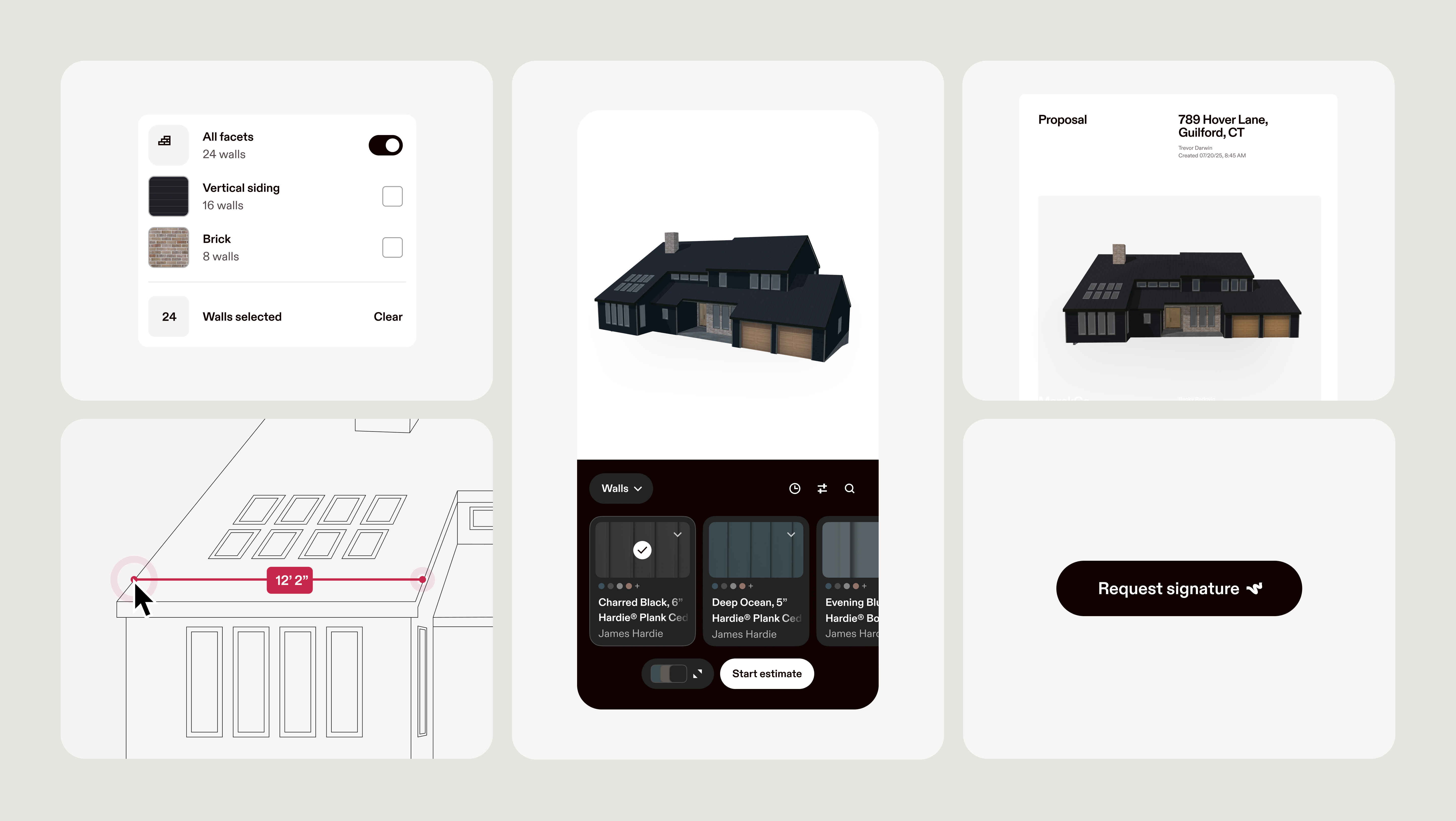

Digital takeoff tools: Platforms like Hover allow you to perform takeoffs directly from digital plans, increasing accuracy and efficiency.

-

Integration with estimating software: Integrate takeoff data with estimating tools to generate comprehensive cost analyses and proposals.

-

Cloud-based collaboration: Share takeoff data with team members and stakeholders in real-time, facilitating better communication and decision-making.

Best practices for optimizing framing takeoffs

-

Stay updated on material prices: Regularly check current prices to ensure accurate cost estimates.

-

Standardize processes: Develop templates and checklists to maintain consistency across projects.

-

Train your team: Ensure that all team members are proficient in using takeoff tools and interpreting plans.

-

Review and revise: Double-check takeoff calculations and adjust for any changes in project scope or design.

Conclusion

Mastering framing takeoffs is crucial for the success of any construction project. By following a systematic approach and leveraging modern tools, contractors can enhance accuracy, reduce waste, and improve overall project efficiency. Embracing these practices not only benefits your bottom line but also positions your business for long-term success in the competitive construction industry.