In 2019, Schisler joined Shumaker, which his dad purchased in 1986. The company has a long history in Maryland & Pennsylvania dating back to the 1940s. Under Schisler’s father, the business was doing well, but was admittedly not very scalable. Upon taking over operations, Schisler focused on using technology to create economies of scale and efficiencies to help his small team keep up with the demands of the industry. He aspired to provide his company the opportunity to grow and discovered HOVER to help him do that.

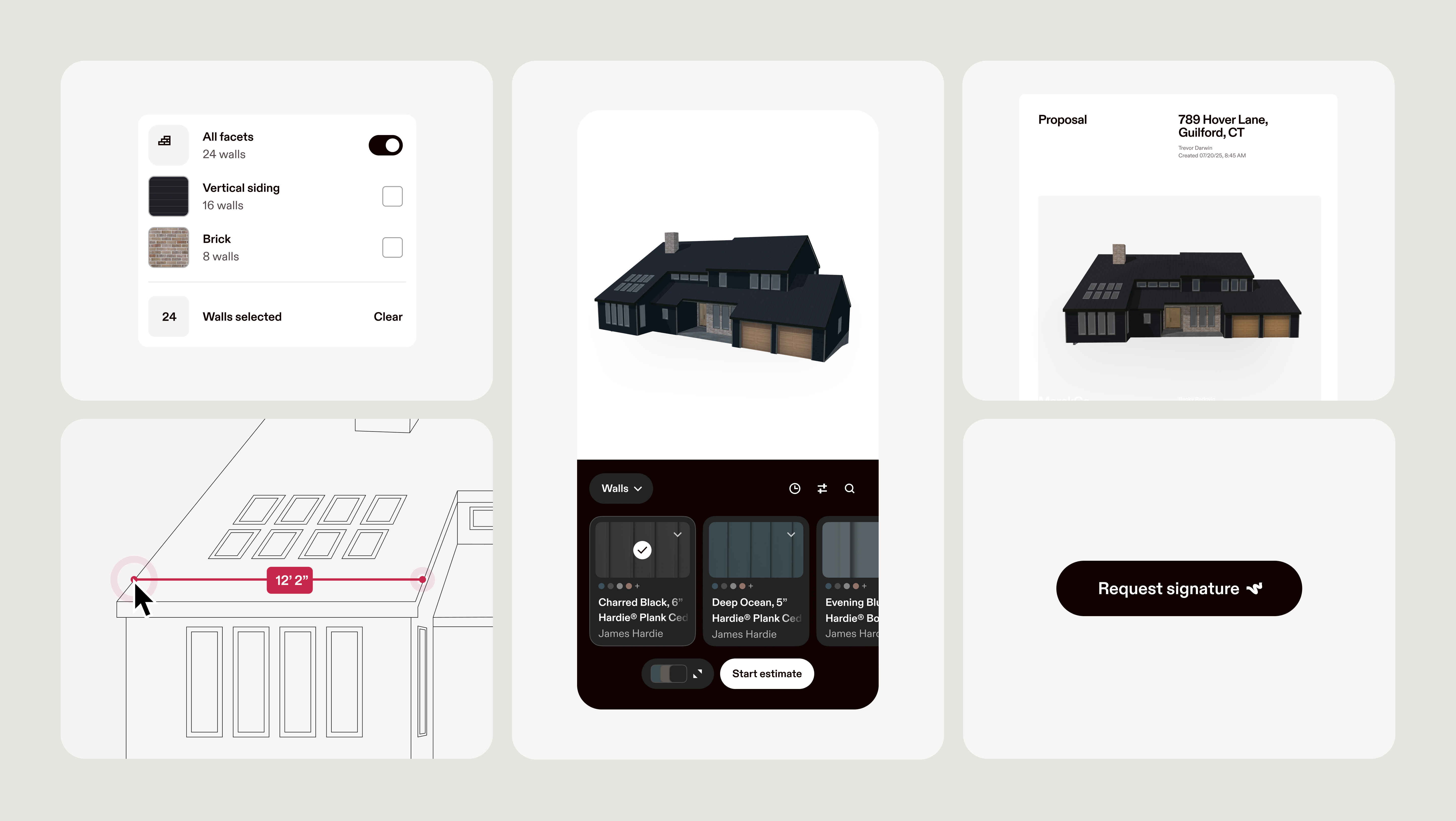

“If you have a business or contracting company that is looking to scale, HOVER is designed to help you do that,” says Tyler Schisler, co-owner of Shumaker Roofing. “When I heard Direct Ordering was a part of what HOVER offers, I knew it would make running my business easier.”

Tyler Schisler

Co-Owner at Shumaker Roofing

Schisler was first introduced to HOVER after having seen it used by Travelers Insurance when working on restoration jobs. HOVER offered increased accuracy over his team’s hand measurements and made sure he had a record of all the details of the property's exterior. Just as importantly, it helped him engage smarter and faster with carriers. “With insurance companies that do use HOVER, the measurements come back exactly the same. We know what they will go off of, and the process is seamless,” says Schisler. “It cuts the time it takes to measure a property by one day into minutes.” It wasn’t long before Schisler wanted to enlist HOVER to help him harness the power of those measurements to create workflow efficiencies for his production managers and project managers.

Shumaker Roofing’s production team began using HOVER’s Direct Ordering tool to place material orders in 2021; HOVER calculated the needed material quantities for each job in seconds and allowed them to instantly place material orders with their supplier all in one place. This change enabled Shumaker to produce more jobs and grow their business by over 30%.

Shumaker enlisted HOVER’s support to set up their account so that every order was calculated using their company’s unique installation preferences. With HOVER measurements already in the platform, all the project managers needed to do was specify the job scope and click to submit the order. In the past, Shumaker used a robust spreadsheet that Schisler’s father created. The information was then exported and sent as a Word document to the materials supplier. Direct Ordering removed the time required for a number of steps; from gathering dependable information from sales, calculating material quantities, to reentering material order details into different platforms. Now, the office manager reviews new jobs and places each order in minutes all from within HOVER.

“Direct Ordering allows me to build our business and not be so hands-on. I don’t need to worry about whether we have enough ridge vent. I leave that to the team. And the team relies on HOVER so there’s no reason for an inaccurate material order.”

Tyler Schisler

Co-Owner at Shumaker Roofing

Because of Direct Ordering, the Shumaker team produces jobs faster and knows every material order is accurate and complete. Interested in growing your company with HOVER’s Direct Ordering?